Oil & Gas

HDPE Applications and Uses in the Oil and Gas Industry

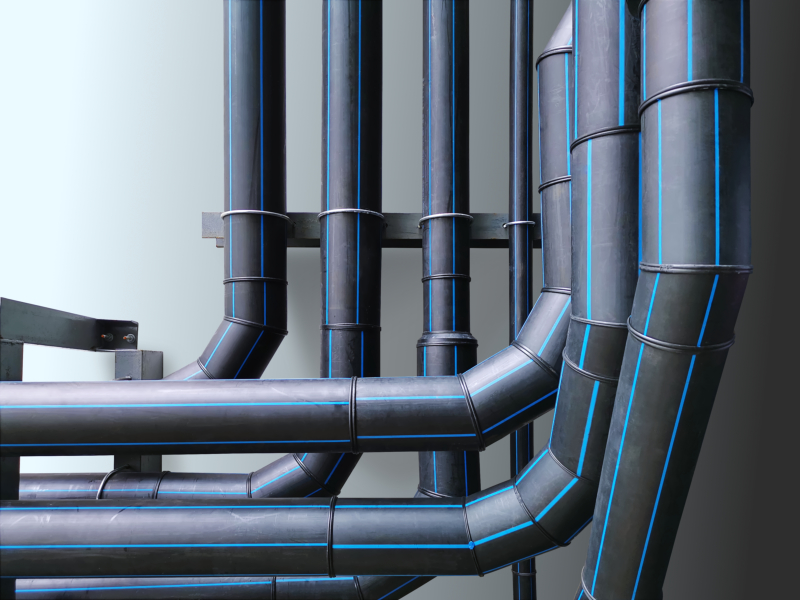

HDPE PE 63 pipes are used primarily for transporting fluids and gases under low to medium pressure conditions. These pipes are highly resistant to corrosion, which is crucial when dealing with harsh chemicals and aggressive substances found in oil and gas production. Their flexibility allows for easier installation in difficult terrain and reduces the risk of damage due to ground movement. Additionally, HDPE PE 63 pipes are used for various applications like water injection systems, waste management, and pipeline repairs, offering long-term reliability and cost-effectiveness in the industry.

Wastewater & Water Industry

HDPE Applications and Uses in the Wastewater & Water Industry

In the wastewater and water industry, HDPE PE 63 pipes are widely used for transporting both potable water and wastewater due to their high resistance to corrosion and chemicals. These pipes are commonly found in municipal water supply systems, stormwater drainage, and sewage treatment plants, offering a durable solution for managing water flow. Their flexibility and ability to withstand extreme temperatures and pressures make them ideal for both above-ground and underground installations. Additionally, they provide a cost-effective alternative to traditional piping materials, reducing maintenance and replacement costs over time.

Agriculture & Irrigation

HDPE Applications and Uses in Agriculture and Irrigation

In agriculture and irrigation, HDPE PE 63 pipes are essential for efficient water delivery systems. These pipes are commonly used to distribute water across large farming areas, ensuring consistent irrigation for crops. Due to their resistance to chemicals, UV light, and environmental stress, they are ideal for handling both potable and non-potable water. Their flexibility and durability allow them to be installed in challenging terrains, reducing maintenance needs and downtime. Additionally, HDPE pipes are used in fertigation systems, helping to deliver fertilizers directly to the plant roots in a controlled manner, enhancing crop yields.

Chemical Processing Industry

HDPE Applications and Uses in the Chemical Processing Industry

In the chemical processing industry, HDPE PE 63 pipes are widely utilized for transporting aggressive chemicals and corrosive substances due to their exceptional chemical resistance. These pipes are ideal for handling acids, alkalis, and solvents, ensuring the safe transfer of hazardous materials without compromising integrity. Their high strength and durability make them suitable for both pressure and gravity-based systems, reducing the risk of leaks or system failures. Additionally, HDPE pipes’ smooth interior surfaces minimize the buildup of deposits, enhancing flow efficiency and reducing maintenance needs in complex chemical systems.

Manufacturing & Processing

HDPE Applications and Uses in Manufacturing and Processing

In manufacturing and processing industries, HDPE PE 63 pipes are commonly used for transporting chemicals, hot liquids, and gases due to their excellent chemical resistance and ability to withstand high temperatures. These pipes are also crucial in the construction of fluid handling systems, where their durability and flexibility reduce the risk of leaks and ensure the safe delivery of materials. Additionally, HDPE pipes are employed in various sectors for drainage systems, sewage treatment, and waste management applications, where they offer long-lasting solutions without compromising performance. Their lightweight and ease of installation make them ideal for projects that require rapid deployment and minimal maintenance.

Coastal Resource Group offers expertly designed, flexible, and durable piping solutions built to withstand tough marine and industrial environments.

Coastal Resource Group offers expertly designed, flexible, and durable piping solutions built to withstand tough marine and industrial environments.