In industrial systems, gaskets are essential to maintaining a leak-free seal between two static surfaces. Whether used in flanged pipe connections, compressors, or pressure vessels, their reliability affects safety, uptime, and environmental compliance. But even with the best materials, gasket failure is a recurring issue in many industrial operations. These failures often lead to costly shutdowns, hazardous leaks, and extended maintenance cycles.

Knowing what causes these problems and how to prevent them can significantly improve the life expectancy of sealing components and reduce maintenance overhead.

What Happens During Gasket Failure

When a gasket no longer provides a proper seal, fluids or gases may escape from the joint. Depending on the media, this could mean anything from water leakage to toxic chemical exposure. Gasket failure typically occurs when the gasket material is unable to withstand the conditions it is exposed to, such as excessive pressure, temperature, chemical degradation, or mechanical stress.

According to a peer-reviewed study on flange joint failure, these breakdowns often result in sudden blowouts, long-term loss of compression, and uncontrolled leakage that puts both systems and personnel at risk.

- Blowouts at the flange;

- Persistent leaks around bolts;

- Warped, cracked, or split gasket material; and

- Loss of torque or compression.

Not only do these issues affect productivity, but they also jeopardize worker safety and regulatory compliance, especially in facilities handling hazardous substances.

Most Common Causes of Gasket Failure

Gasket failure can often be traced back to a small set of root causes. Identifying these early helps extend component life and avoid unplanned downtime in high-pressure or corrosive environments. A research study on catastrophic gasket failure modes confirms that many industrial sealing issues stem from incorrect installation practices, unsuitable material selection, or long-term mechanical stress within bolted flange joints.

Improper Installation

One of the most common reasons for gasket issues is incorrect installation. Gaskets that are over-torqued, misaligned, or reused can quickly lose their sealing integrity. Inconsistent bolt loading or uneven torque application often causes the gasket to deform or crush, creating paths for leaks.

Incompatible Materials

Every gasket material is rated for certain pressure, temperature, and chemical resistance ranges. Using a gasket that cannot withstand the application’s environment, such as installing a non-metallic gasket in a high-temperature steam line, results in rapid degradation. Material compatibility should always match the media, operating pressure, and temperature.

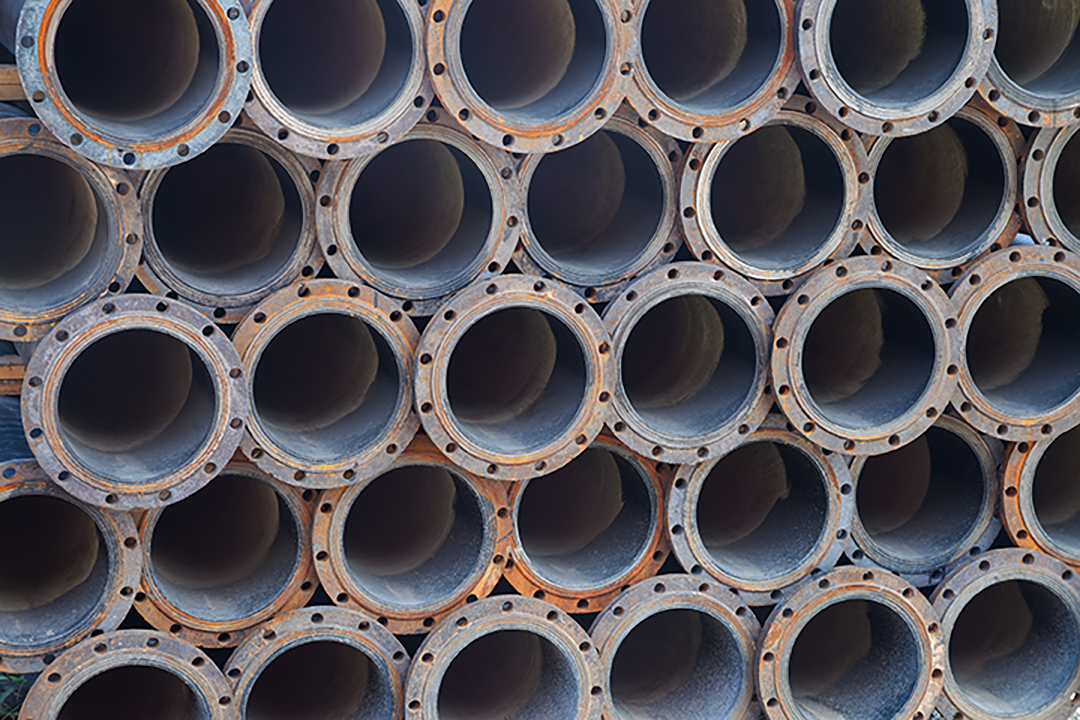

Flange Surface Damage

Damaged or corroded flange surfaces compromise the gasket’s ability to seal. Rust, gouges, or warping prevent proper compression and seating. Before installing a new gasket, flanges should always be inspected and resurfaced if necessary.

Excessive Thermal Cycling

Repeated heating and cooling cause expansion and contraction at the joint. Over time, this movement loosens bolts, weakens the gasket material, and creates gaps. Applications with frequent thermal cycles must use materials with proven recovery and flexibility characteristics.

Vibration and Mechanical Movement

High-vibration equipment, such as pumps and compressors, causes micro-movements that slowly wear down the gasket. Eventually, it begins to extrude or fracture under stress. In dynamic systems, gaskets with high compressibility and recovery rates are needed.

Creep and Relaxation

Gaskets made from softer materials may experience creep, which is the gradual deformation under constant stress. This leads to a reduction in surface pressure and a drop in sealing performance over time. Gasket relaxation is accelerated by heat, vibration, and improper torque loading.

Best Practices to Avoid Gasket-Related Sealing Problems

Prevention strategies rely on proper selection, installation, and monitoring. Below are five best practices to improve gasket lifespan and minimize sealing problems:

Follow The Manufacturer’s Torque Specs

Always refer to the manufacturer’s recommended torque values. Improper torque is one of the most common installation mistakes. Use a calibrated torque wrench and apply a star-pattern technique to ensure even compression across the gasket.

Use Flange Condition Monitoring

Before each installation, inspect flanges for flatness, corrosion, and surface scratches. Clean surfaces thoroughly and measure with precision tools to detect distortion or pitting that may affect the seal.

Match Gasket Material to Application

Material selection should be based on the full operating conditions of the joint. Consider the type of media, maximum and minimum temperatures, pressure levels, and potential exposure to corrosive chemicals.

Avoid Reusing Gaskets

Once compressed, gaskets lose their recovery ability. Reusing old gaskets, even if they appear intact, often results in improper sealing. Always install a new gasket during maintenance or disassembly.

Train Personnel on Installation Techniques

Ensure technicians are trained in correct installation methods, torque procedures, and gasket handling. Human error can often be reduced through standardized training and quality checks.

Common Gasket Issues by Industry and Application

Each industry faces unique sealing challenges depending on the operating environment, media, and system pressure. Gasket performance is closely tied to how well the material and design match these specific conditions. The table below outlines some of the most common issues and the gasket types typically used in key industrial sectors.

| Industry | Common Issues | Typical Gasket Materials |

| Oil & Gas | High-pressure leaks, chemical attack | Spiral wound, graphite, PTFE |

| Petrochemical | Thermal cycling, corrosive vapor exposure | Compressed fiber, metallic gaskets |

| Water Treatment | Low-pressure leaks, microbial degradation | EPDM, rubber gaskets |

| Power Generation | Steam leaks, joint movement | Graphite, spiral wound |

| Food & Beverage | Hygiene failures, swelling | PTFE, silicone |

Monitoring and Inspection for Long-Term Maintenance

Sealing performance should be part of regular maintenance checks. Schedule inspections for high-risk equipment, especially where flange joints are exposed to high pressure, vibration, or chemicals. Use leak detection methods such as dye penetrants or ultrasonic leak detectors. Log all maintenance activities to track gasket lifespan and failure patterns across systems.

When to Replace a Gasket

Proactive gasket replacement reduces the risk of unplanned downtime. Consider replacement when:

- Gasket material shows signs of extrusion, fraying, or compression set.

- Leaks recur even after re-torquing bolts.

- Maintenance cycles are approaching end-of-life projections.

- Equipment has undergone major thermal or pressure changes.

Planning replacements during scheduled shutdowns minimizes impact on production and ensures continuous system reliability.

Why Industrial Teams Trust Coastal Resource Group for Sealing Solutions

Coastal Resource Group delivers high-performance sealing materials built to withstand the pressures of industrial operations. From our facilities in La Porte and Seguin, Texas, we serve critical sectors throughout the Eagle Ford Shale and Gulf Coast refinery regions with fast shipping and expert support.

We supply:

- Reliable gaskets for high-pressure, high-temperature, or chemically aggressive environments.

- Flange accessories and torque tools to support proper installation.

- Sealing materials matched to your media, pressure, and temperature needs.

- 24/7 service and rapid delivery for urgent maintenance schedules.

Our team understands the role proper sealing plays in preventing leaks, avoiding downtime, and protecting assets. Whether you’re maintaining refinery systems or replacing pipeline gaskets, Coastal Resource Group is ready to support your goals with the right materials and fast delivery.

Contact us today to request a quote and discover how Coastal Resource Group can support your next project with confidence.